Self-Adhesive Gaskets

We manufacture self-adhesive gaskets and adhesive gasket materials for a range of industries and operationg conditions. If you need technical advice on the right gasket and adhesive to use for your application then please do not hesitate to contact us.

What follows is a general guide to self-adhesive backed gaskets.

What are self-adhesive gaskets?

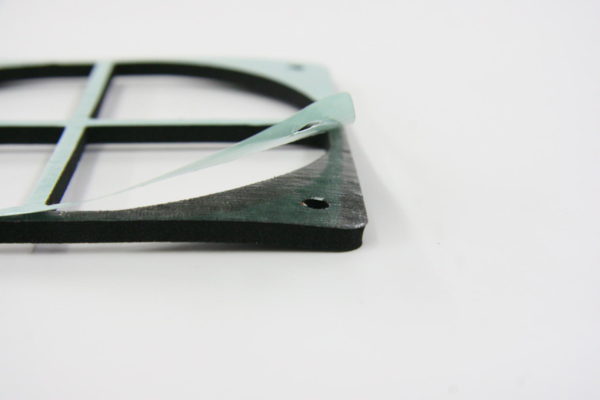

Self-adhesive gaskets are gaskets that have been covered with an adhesive backing. Release paper covers the adhesive and preserves its integrity until it is ready to be used. When it is time for the gasket to be installed, the release paper is peeled off and the gasket is fixed to the surface where it is being fitted. The adhesive is used generally as an aid to fitting or assembly, rather than to perform any other structural or sealing function.

The benefit of self-adhesive is that it enables gaskets to be installed in a much more clean and efficient way that they otherwise might be without adhesive , or by glue being added in the process of the gasket being fitted.

Why use a self-adhesive gasket?

Self-adhesive gaskets are generally used where there is a danger of the gasket slipping, or becoming deformed, in the process of being fitted. Adhesives are also used in environments where, for safety reasons, time is a limiting factor (such as in a mining or a sub sea environment) as gaskets must be fitted very quickly.

As such, self-adhesives are generally used to help keep the gasket in place until the flange bolts are sufficiently tight – to stop slippage or deformity of the gasket during the sealing process.

Adhesive backed gaskets are also used on removable panels (in, for example, electrical switchgear cabinets), where the cabinet requires a gasket to increase IP rating. This allows the panel to be removed quickly for inspection, whereas it would be time consuming and dangerous for the gasket to come off separately.

Can I use a self-adhesive gasket?

If you think your application calls for an adhesive gasket, whether a self-adhesive gasket can be used will come down to the operating environment (and questions of temperature, pressure and chemical resistance) and the nature of the surface to which you want to stick the gasket. Mating surfaces must usually be free from dust and chemicals (such as solvents), which migh prevent the adhesive from working properly.

Once we know the environment and operation conditions under which you want the gasket and adhesive to function, we can help you specify a gasket material and adhesive appropriate for your application.

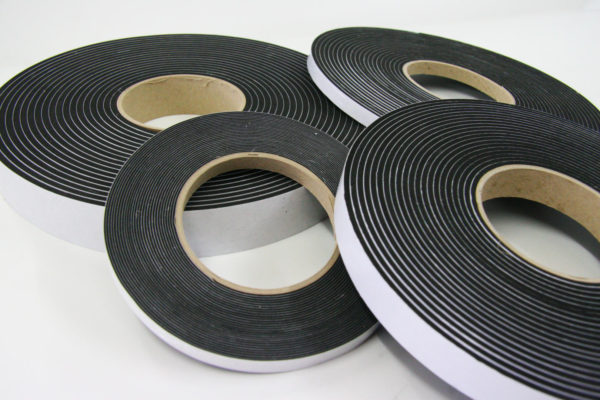

What adhesives are available?

There are many different types of adhesives that can be used with gasket materials (including 3M VHB). The most common types are hot-melt and acrylic based adhesives. A hot-melt adhesive provides a light tack that will help fix a gasket in place, but its tackiness will reduce over time. In contrast acrylic based adhesives can be moved and repositioned once initially put in place, as they only acquire their full strength after several hours.

The type of release paper used with the adhesive can also make a difference. Tissue carriers, for example, allow for flexibility while shim carriers help maintain dimensional stability. Scrim carriers allow for reduced stretch and the application of a single adhesive layer.

How long do adhesive gaskets last?

Gaskets are backed with live adhesive so they will eventually dry out. The majority of adhesive backed seals work by tack only (no chemical change occurs) and so they have a limited shelf-life in which they can be used. These gaskets ahould ideally be used within six months of purchase, although many factors can affect this, such as transport and storage conditions.

For similar reasons, the adhesive will only last for a certain amount of time once the gasket is in situ. (Recall that gaskets are generally backed with adhesive simply to help with fitting, rather than to perform any more serious function). If you require the adhesive to last for a longer time scale, a two part adhesive can be used when fitting.

Effects on temperature, pressure, chemical resistance and performance

Adhesive should not have any adverse effect on the function of a gasket. Having said this there are a number of things to keep in mind: adhesives will have very little effect on the pressure rating of a gasket, but the same cannot be said for temperature and chemical resistance.

Ordinary adhesives only function up to a range of +50 to +60ºC. If your operating environment has a higher temperature then you may require a high temperature acrylic adhesive which will function from -30ºC to +160ºC.

Adhesives have little or no chemical resistance. If a specific chemical resistance is an integral part of your specification it is likely that an adhesive should not be used.

Limitations of self-adhesive gaskets

Adhesive backing can be applied to many different gasket materials, including both solid and foam rubbers (such as neoprene, nitrile, EPDM and viton). It is difficult to use adhesive with silicone rubber as it is such an inert material that adhesives will not bind to it. Similarly, PTFE is so inert that it usually requires etching (to make one of the surfaces rough) before adhesive backing can be applied to it.

Which industries are adhesive backed gaskets commonly used in?

Self-adhesive seals are found in many industries. Typical applications include door seals, lid seals, gaskets around windows and on electronic equipment displays.

Adhesive gaskets are commonly used in electronics (for example in LCD screens). Machine manufacturers, such as injection moulders and milling machines, use gaskets internally to perform certain functions (mounting etc.). These gaskets are typically mounted with adhesive to ensure that they stay in the same place.

On some exceptionally large gaskets self-adhesive is used to make them easier to keep in place whilst the flange bolts are tightened.